Sustainability has been part of our corporate strategy since 2008 – with a clear goal: climate-neutral production sites.

Our most powerful lever: decarbonizing production through our own supply of green energy. In addition, regional raw materials, fewer animal-based ingredients, and recyclable packaging all make a measurable contribution to reducing emissions.

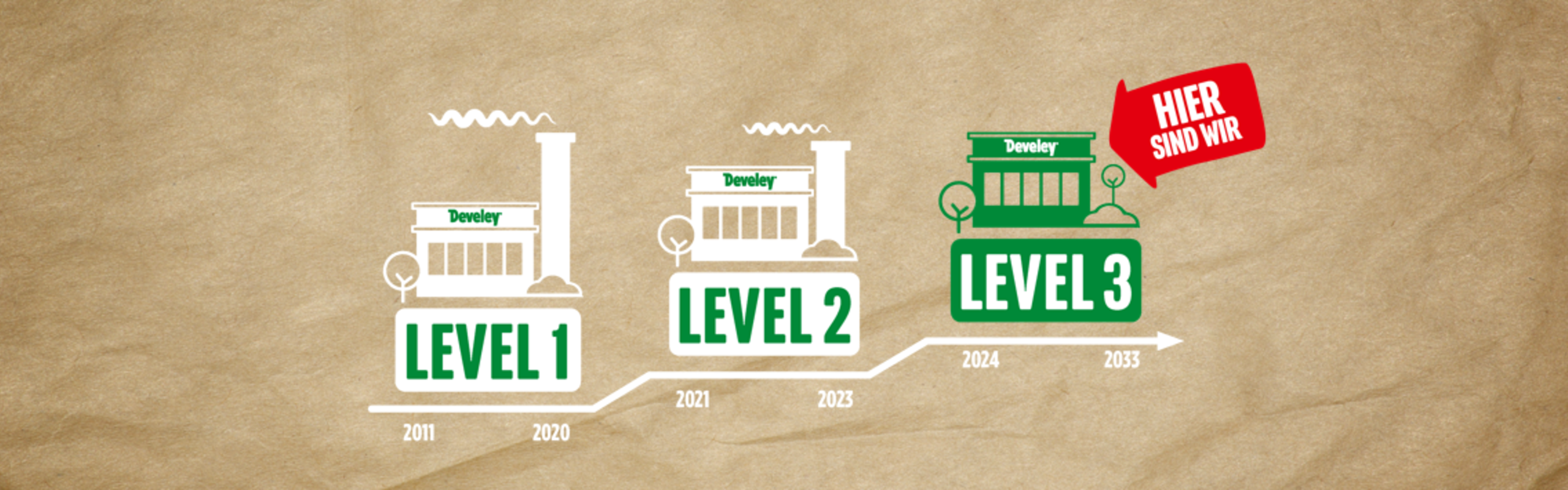

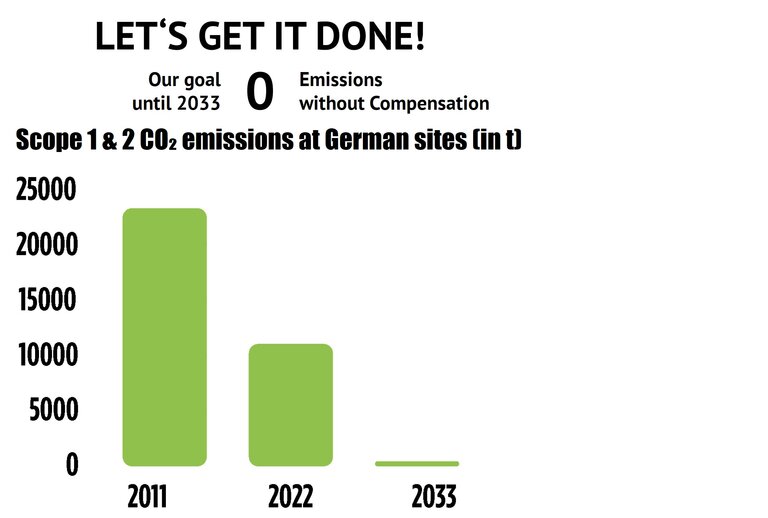

Since 2008, Develey has been pursuing the goal of climate-neutral production – based on a clear three-level model: First, CO₂ reduction through technology; then, compensation measures; and today, the focus is on true climate neutrality through our own renewable energy sources, without relying on carbon offsetting.

Our target: to achieve genuine climate neutrality in Germany by 2033 and internationally by 2038 – through targeted investments in zero-emission solutions. We are fully aware that the majority of our emissions fall under Scope 3. That’s why we are currently working on setting an ambitious target in this area as well.

By the end of 2025, we will also formally commit to the Science Based Targets initiative (SBTi).

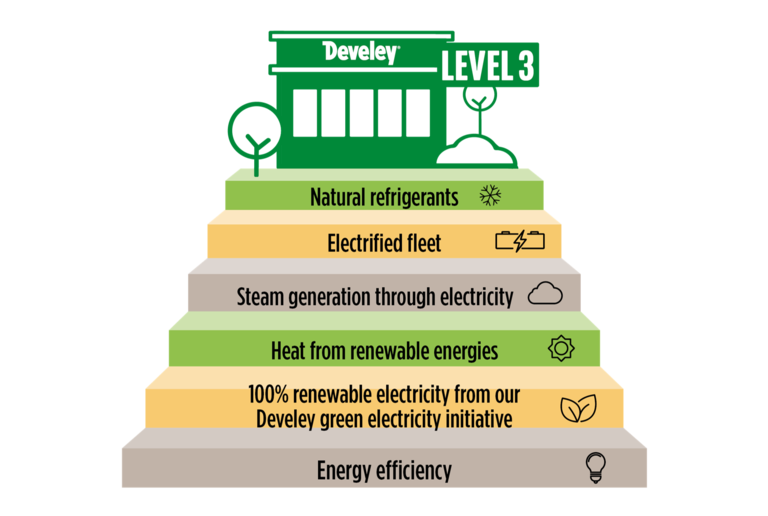

We aim to reach climate neutrality at our sites through a comprehensive set of measures. At each individual location, we prioritize these actions based on where they can have the greatest impact.

Here, using a model site as an example, we highlight the key building blocks on our path to net zero emissions.

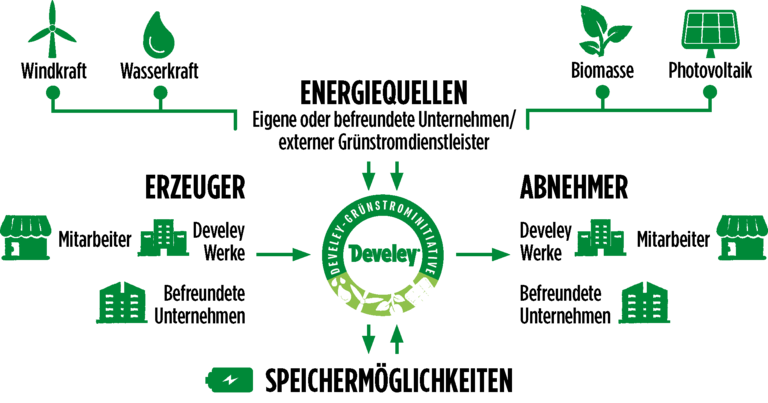

Electricity demand and generation fluctuate – and our solution is a virtual power plant that bundles self-generated green electricity across sites and distributes it according to demand. By the end of 2025, we aim to fully cover our energy needs through this system. Companies with similar goals are welcome to join the initiative and feed in their own green electricity. This way, the shared green power budget grows – and is distributed based on actual consumption.

Develey is one of the pioneers in sustainable energy within the food industry.

In Unterhaching, a groundbreaking flagship project was launched in 2013 with the introduction of a CO₂ refrigeration system and deep geothermal energy. Since then, nearly all processes at the site have been powered by geothermal heat.

Dingolfing also led the way early on: back in 2012, a woodchip heating plant was commissioned, followed by a combined heat and power unit, a photovoltaic system, and a biological wastewater treatment plant.

Today, photovoltaic systems across multiple sites feed into an intelligent green electricity network, enabling site-wide energy optimization.

Our initial focus is on our production sites – but upstream and downstream emissions (Scope 3) also play a significant role, arising from activities such as agriculture, transport, and disposal. We are increasingly analyzing these emissions and have already begun to take action: By using more plant-based ingredients and reducing packaging, we are lowering our first Scope 3 emissions.

What was once disposed of as wastewater is now helping to keep roads safe in winter: As part of a pilot project, Develey has been supplying brine from cucumber production as an eco-friendly alternative to traditional road salt for several years. Around Dingolfing, this has already saved approximately 140 tons of salt and nearly one million liters of water.

Since 2016, Develey has eliminated palm oil from its recipes – and continues to increase the use of plant-based, regional, and seasonal ingredients. Our entire mustard range is 100% vegan, as are many of our gourmet sauces.

Plant-based alternatives not only improve our climate footprint, but also extend shelf life and help reduce food waste. Just by replacing egg yolk, we save around 26,000 kg per year.

Less packaging means less material, lower CO₂ emissions in logistics, and less residual waste. Our challenge: finding the most sustainable solutions while still protecting product quality. That’s why we rely on creative approaches and recyclable materials such as rPET and cardboard.